Sheet Metal Rolling

The process of metal fabrication is one process that continues to grow by every passing day. This is the process that accounts for the manufacturing of all the metallic parts that are used in the manufacturing process. The process of metal fabrication is a very wide process touching on so many things in many areas. Part of the things that come out of this process is the sheet metal. This material as you might know is used in so many places for various functions among the manufacture of motor vehicle parts among others. Given the many uses of the sheet metal, it comes with various fabrication procedures depending on what the material is intended to do late on.

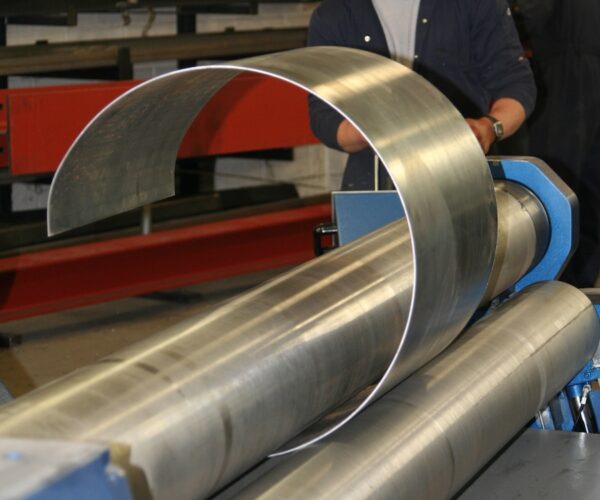

One process that sheet metal undergoes in its fabrication process is the Sheet Metal Rolling. If the required product at the end of this process is a cylindrical piece of sheet metal then this process will have to occur. It is a very common process in the metal fabrication industries carried out by people who are well skilled and experienced as well.

Other than that, this process also relies on the accurate use of machines. It is a very delicate process that has to be carried out with the most accuracy. A simple miss during the process will mean the whole process will have to be repeated. For this reason, this a process that requires some proper planning which proper executions plan later on. If you are about to get into this business then you need to know that there are some people who carry out this process but never get the desired results.

If you are not so careful then you will most likely register poor results out of this process. The best way to carry out this process is to look for all the essentials required to make this process a success. Once you have these essentials you need to plan your work and know exactly what parts you need to create. The process of sheet metal rolling is also one process that you need to carry to carry out within the shortest period of time. As you plan to get into this business you need to make sure you have the required essentials to carry out this process with the required speed.

To make this possible you need to look for the right machines that will help you to create the best rolls well on time. The only place that you get the right machines for this process in the state of Michigan is Contract Manufacturing Specialists of Michigan. These experts have the best machines that you can rely on for this process. In fact, this is the best place where you can find all the equipment you need for the entire metal fabrication process. Since the outcome of any sheet metal process lies on machines used for this process it is only right that we talk about that as well.

We need to look at some of the ways that you can use to find the best machines for this process. How exactly can you find the right machines that will help you to come up with the rolls that you desire we are going to find out about that. Before we get to that it is essential for you to know that machines alone cannot get you the results you need out of this process. You also need to invest in someone who will help you to run these machines and help you out with the rolling process perfectly.

If you do not do this then you will not be able to realize the desired rolls even with the right machines. You need someone who will carefully oversee this process helping you to realize the results that you need. Depending on the rolls that you need to come up with, you need to make sure you have the right machines for the process. You also need to determine the thickness of the sheet metal that you are going to work with. This is in fact will help you to choose the right machine for this process. If you assume this factor then you are more likely to pick a wrong machine that will not get you the right bends.

Once you have all these things then you can consider the factors below to help you find the best machines for this process. With the right machines as well as the manpower then you will be able to realize the best results out of this whole procedure.

What do you seek to achieve with the machines?

There have been cases where people bought machines for the Sheet Metal Rolling process simply because of a project that they had. This is one thing that you need to avoid doing at any given time. If you have to buy any machines for this process then you need to do so based on your day to day activities.

You need to gauge your projects and look for a machine that will help you to work on your projects perfectly. To find such a machine you need to look at the specifications of the machines then look if they match that of your work. If you do this then you will be able to make the most out of these machines.

However, if you choose machines simply because of a single then you will find it hard working on some projects later on. The only way that you can work on your current projects and many others to come is by looking for the right machines that will serve you perfectly.

Consider the machine rolling width capacity

The other essential thing that you need to consider is the width rolling capacity of the machine. The machines come with various rolling weight capacities. One that is clear is that these machines do not cost the same. However, you should not use this as an excuse, you need to consider a machine with the right rolling width capacity.

If possible, you need to look for a machine with a rolling width that will suit over 80% of your projects. This way, you will be able to deal with any project that comes your way without any problems. If you choose a machine with a lower rolling width capacity then you will most likely find yourself unable to work on some projects.

Look at the quality of the machine

If you have ever worked with machines then you will know that we have those machines that come in with low quality while others come in with higher quality. You need not make any mistake, for the process of Sheet Metal Rolling you need to look for machines with the best quality. You need a machine that will be able to serve you for a very long period without any problem. You need to insist on the quality of the machines before paying your money on any. You need to know exactly how the machine behaves under extreme conditions as well as its speed.

You do not need a machine that will take a very long period of time working on your project. You need a machine that will deliver quality rolling within the shortest period of time. This is the only way that you can use to realize the progress that you need in this industry. If you pick on a wrong machine then you will find yourself compromising so many things that will eventually affect your productivity.

Consider your production quantity

This is the other important thing you need to consider when before you buy any machine. You need to assess your production quantity and look for the right machine that will suit you well in this regard. For instance, if you have higher production quantities then you need to look for CNC machines which definitely work well to deliver such projects.

The process of Sheet Metal Rolling is one process that relies so much on machines in terms of quality as well as quantity. For this reason, if you are in this business or looking to get into this business you need to look for the right machines that will deliver the best results to you.

Given the quality of staff and equipment that we have, you can be sure of getting the best rates from our brand. To benefit from our services, feel free to call us today. We have a team that is ready to give you the best services all the time.

Our core offerings and services at Contract Manufacturing Specialists of Michigan includes, but is not limited to, the following below:

We service multiple cities throughout the state of Michigan. We provide all the services listed above, and much more in every city throughout Michigan.

If you don’t see your city listed or a specific service listed, don’t worry. All you have to do is contact us by either giving us a call or filling out our online contact form. Then we’ll discover what are some of the top solutions for you, your business, and executing a solid solution.