Sheet Metal Edge Rounding

There are people who ask whether it is essential to carry out the process of Sheet metal edge rounding. Given that this process might be costly people might ask whether it is really essential to carry out this process or not. To start with, this process is very essential on a piece of metal and one that has to be carried out in the best way possible.

There are so many reasons that make this process so essential as we are going to see. We need to look at why this process is so essential and how to carry out the same process. To understand this, we need to take a case of those people who tried working with sheet metal that was not rounded. Sheet metals that come with edges that have not been rounded can be dangerous. This is the most important that you need to take note of. There are so many cases where people working in the sheet metal industries sustained injuries due to the effects of the blurs on the sheet metal.

In fact, there are so many incidents where such things happened. These injuries occurred when these people were trying to load these pieces of sheet metal into the trucks or even in the industry itself. The only way that you can avoid such a thing from happening is by carrying the process of Sheet metal edge rounding.

By removing these burs from the edges of the sheet metal you will make the pieces of sheet metal safe for your use by everyone. No one will have to worry about sustaining injuries while dealing with the same materials. It is one of the ways that you can use to keep the pieces of sheet metal safe for use for your workers or even your clients on the other hand. Everyone knows that press brake machines do not come in at cheap prices. Some of these machines are so costly that some people avoid buying them. Anyone who buys these machines will try anything possible to make sure that the machines together with the bending length as well the tonnage are well protected.

If these machines develop any problems then they will require so much money for them to be repaired and gotten back to full functionality. Some of them even develop problems that send them packing forever. This has led people to look for ways that they can use to protect these machines against any form of threat. There are so many threats to press brake machines among them the way the machines are handled as well as the materials that the machines bend. If you feed sheet metal with blurs into the press brake machine then that will be one way of making sure that the machine is exposed to problems that may shorten its life.

This is not something that you would like at any given time. If for anything, you would like to stay the longest period of time with your machine making sure that the machine continues to serve you in the best way possible. However, it is proven that the burs on the edges of sheet metal can actually be destructive to the tonnage of the press brake machine. If you continue exposing the tonnage of press brake machine to the blurred sheet metal edges then the tonnage will definitely be destroyed after some time. To avoid this from happening you need to carry out a proper edge rounding process on the sheet metal to make sure that it does not affect your press brake machine tonnage.

The other thing we need to look at to understand the importance of Sheet metal edge rounding is the issue of painting or finishing. For any piece of sheet metal that undergoes a fabrication process the process of finishing has to be carried out at some point later on. The outcome of this process depends so much on how this process is carried. For this process to be successful the surface of the sheet metal has to be perfect and uniform. If not this then the finishing process will be very far from what the intended results are.

For you to carry out this process in the right way you need to make sure that the surface you are working on is very uniform. Without this, even with the right people taking on this process you will still not be able to get the results you need. Burs on the sheet metal edges can also make it so hard to carry out this process. if you are looking to carry out this process in the best way and reach the results that you need then you need to carry out a proper deburring process.

You need to carry out this process in such a way that it will leave the whole surface looking smooth before you can carry out the finishing process. These are some of the reasons that make it necessary and essential to carry out the process of Sheet metal edge rounding.

Clearly from the above illustrations, it is right to say that this is one essential process that has to be carried out on any piece of sheet metal. It is not just this process that is essential but rather the manner in which the process is carried out. If this process is not carried out in the right way then it will still not work out. For these reasons, it is essential for you to try you to make sure that the process of Sheet metal edge rounding is carried out in the right way whether you are doing it by yourself or hiring someone to do it for you.

To make this whole process a success there are some things that you need to have which is what we are going to look at now. What exactly do you need to make the process of Sheet metal edge rounding a success? The following are some of the things that you need that will help you to carry out this process perfectly.

Look for the right machines

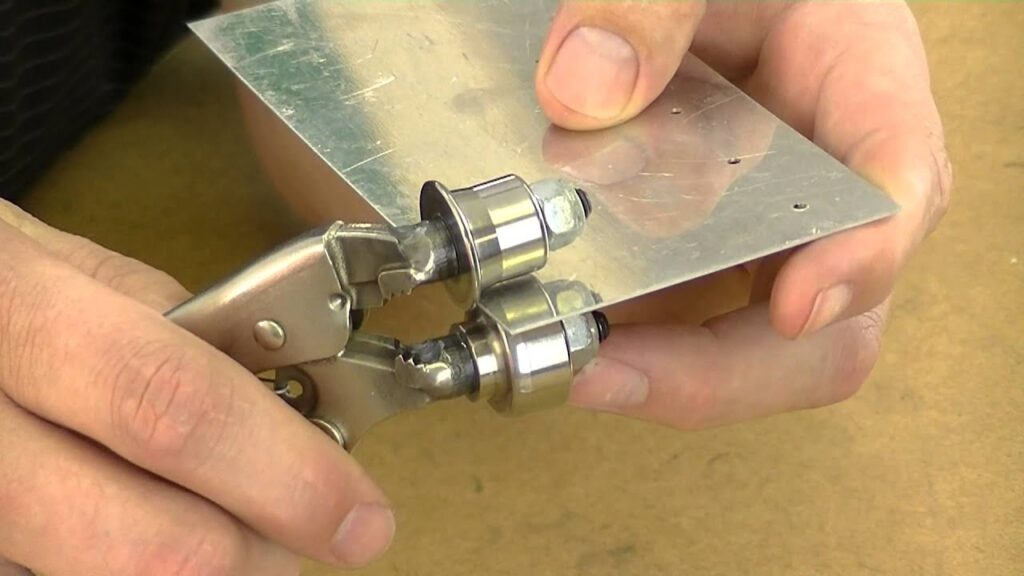

The process of sheet metal edge rounding is one process that has to be carried out carefully using the right machines. There are so many things that make it essential to use the required machines for this process among them accuracy among other things. Remember we said for the best results out of this process, the whole process has to be thorough. If the process is not carried out this way then it will definitely require a repeat process which will be costly. To avoid such a thing from happening it is essential for you to look for the right machines that will help you to carry out this process.

If you are in the state of Michigan you need to head to Contract Manufacturing Specialists of Michigan for the best machines that you can use for this process. These experts have the best machines that you can for this process and the other metal fabrication processes.

Once you have these machines it will be possible for you to carry out this process in a proper way and realize your desired results.

Manpower is very key

The process of Sheet metal edge rounding comes towards the end of the fabrication process. Other than the other things, it is one process that has to be carried out fast and properly. As you look for people to carry out the same process for you need to make sure the people you choose will carry out the process for you fast and perfectly. If you do not do this then you may be forced to out this process again for the second time something that you would not like.

The essence of the Sheet metal edge rounding process cannot be overlooked, this is a very essential process that comes with its own benefits. The factors listed above are some of the top benefits of the same process.

Given the quality of staff and equipment that we have, you can be sure of getting the best rates from our brand. To benefit from our services, feel free to call us today. We have a team that is ready to give you the best services all the time.

Our core offerings and services at Contract Manufacturing Specialists of Michigan includes, but is not limited to, the following below:

We service multiple cities throughout the state of Michigan. We provide all the services listed above, and much more in every city throughout Michigan.

If you don’t see your city listed or a specific service listed, don’t worry. All you have to do is contact us by either giving us a call or filling out our online contact form. Then we’ll discover what are some of the top solutions for you, your business, and executing a solid solution.